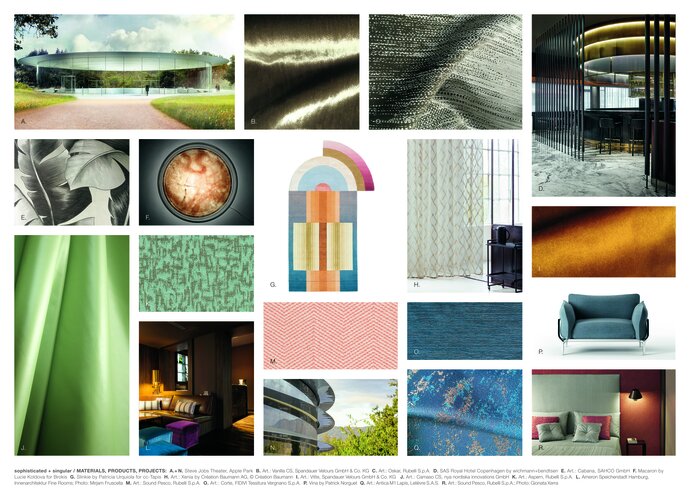

Sustainable and Innovative: Trevira’s Product Developments

At the Heimtextil 2019, Trevira will be presenting important new developments in the “Product Developments by Trevira + Partners” Trevira Lab. The function and nature of these developments have significantly contributed to the expansion of Trevira’s portfolio of flame retardant products. One important developmental focus has been on recycling and sustainability.

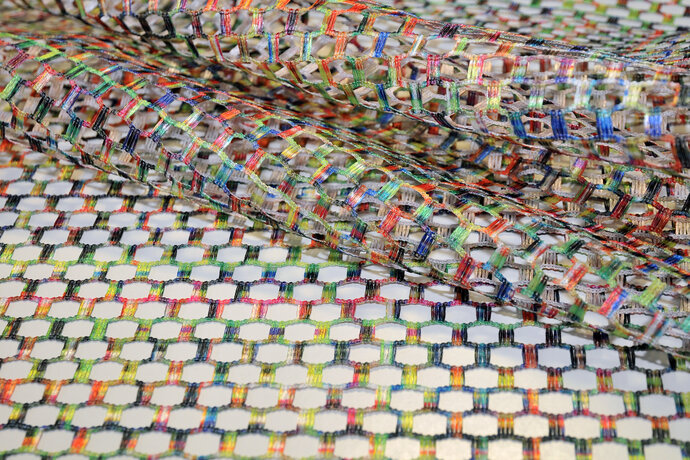

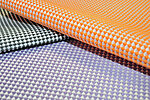

This included flame retardant filament yarns made from recycled PET bottles. For these products, Trevira relies on an especially high-quality raw material supplied by our parent company, Indorama Ventures, which is based in Thailand. Indorama recycles PET bottles to make regranulate for the production of polyester. Since only transparent PET bottles are used in Thailand, the bottle flakes and the chips obtained from these flakes are of a particularly good, very uniform quality. By adding a flame retardant additive, which is securely anchored in the fibre or filament, Trevira uses the chips to produce flame retardant filament yarns that are made from 100% recycled materials. Indorama’s regranulate carries the certificates GRS (Global Recycled Standard) and RCS-NL (Recycled Claim Standard). At the trade fair booth, Trevira will present a woven piece dye from Schmitz Textiles GmbH + Co. KG that is made solely from Trevira’s flame retardant filament yarns consisting of the recycled material. Flame retardant recycled Trevira fibres are also in the development stage.

© Photo: Trevira GmbH/Schmitz Textiles GmbH + Co. KG