Product range

Depending on the degree of polymer modification, Indorama Ventures low-melt yarns have considerably lower melting temperatures than standard polyester. This type of yarn melts when heat is applied during the thermal textile finishing process and stiffens or rather stabilises the textile surface. This function provides both economic and ecological advantages:

- The stabilisation or rather stiffening process is achieved exclusively through thermal finishing and can be specifically influenced through heat, pressure and retention time. This means that chemical binding or coating agents are not required.

- Energy-intensive wet finishing with subsequent drying process and a potentially necessary filtration of exhaust air can also be omitted.

- Single material products based on 100% polyester are easy to recycle.

- Indorama Ventures low-melt yarns are certified in accordance with the OEKO-TEX® STANDARD 100.

The following variants or combinations are available:

- 100% low-melt polyester yarns, in raw white; spun-dyed also available on request

- hybrid yarns made from low-melt polyester yarns and PET filaments, in all current texture technologies, whereby the PET component is also available as spun-dyed

- hybrids made from low-melt polyester yarns and flame retardant PET yarns, in all known texture technologies, in raw white and spun-dyed

The low-melt content in a hybrid yarn may also be referred to NSK (German for niederschmelzende Komponente).

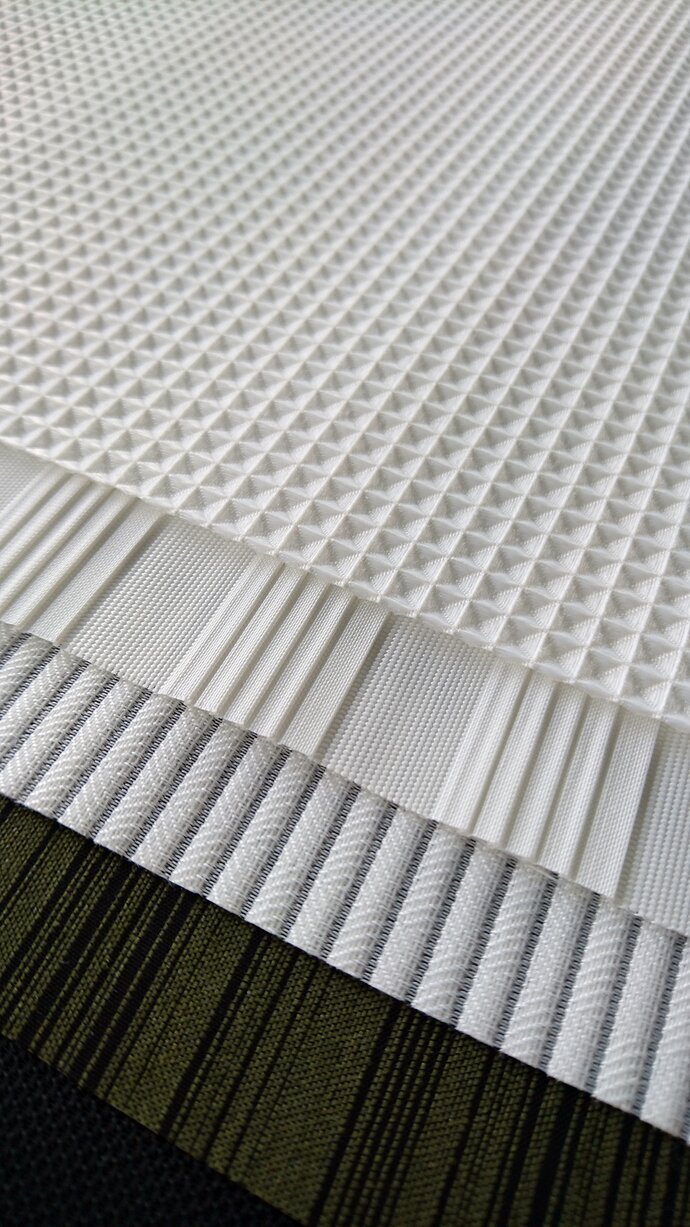

Using the low-melt content in the yarn or rather in the surface structure, the degree of stiffening can be influenced. Thus, the low-melt yarn increases the yarn slippage resistance of the textile surface and can prevent the fraying of woven or layered fabrics. Cut-outs or patterns using laser cuts can also be implemented. The stiffening process also enables the creation of three-dimensional textile structures that retain their shape.

Some of these yarns are available in different versions:

- fine to coarse

- dull to shiny

- with a more or less textile appearance (DTY or ATY yarns)

- with a more or less stiffening low-melt content

- with raw white and/or spun-dyed yarns

There are many possible combinations and they can be individually adapted to each respective purpose. End products can have a textile appearance and can be dyed and printed but also pleated and crushed and they can be formed into nearly any shape. Textiles with a three-dimensional surface may also have a positive effect on the acoustic properties.