Trevira at the 2020 Heimtextil trade fair:

A thriving partnership – value-creating innovations – future-oriented applications

Joint booth with Trevira CS customers and partners

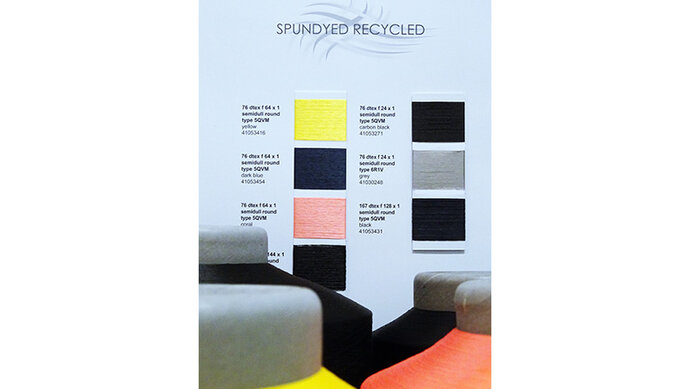

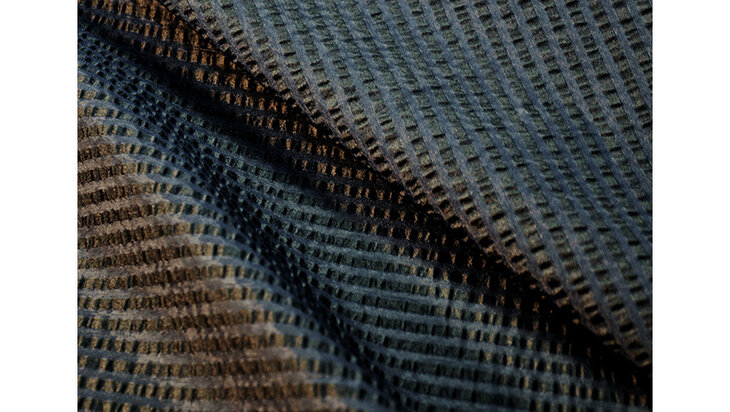

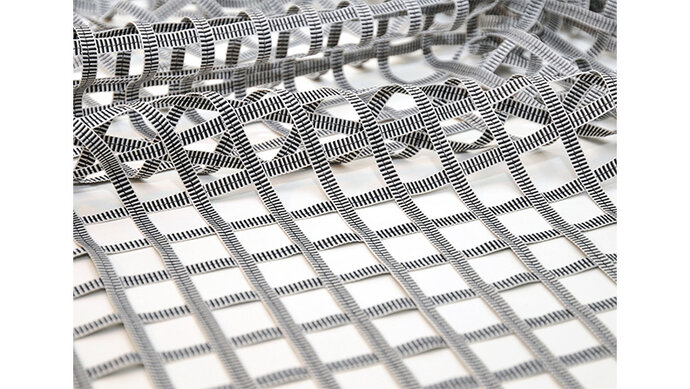

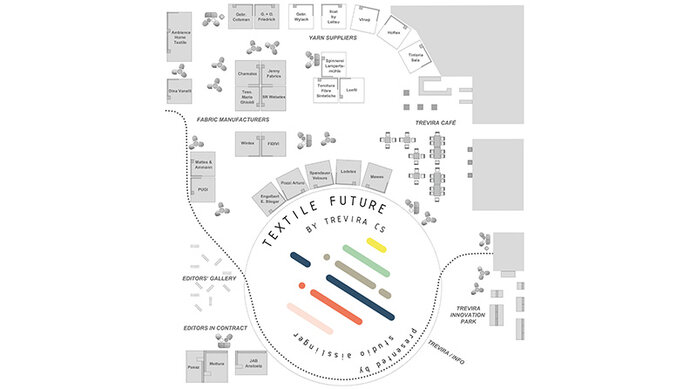

Trevira presents itself once again with its successful trade fair concept at the 2020 Heimtextil trade fair. The manufacturer of high-quality flame retardant polyester fibres will present its products at a stand measuring more than 2,000 square metres. Together with 31 of its major customers, Trevira will cover the entire textile value chain: from the fibre production and yarn manufacture, to the colouring, weaving and warp and weft knitting stages, to the textile editor. Trevira’s customers will present their Trevira CS collections for the home textile sector and the contract market at individual stands, thus demonstrating their contribution to the textile value chain.

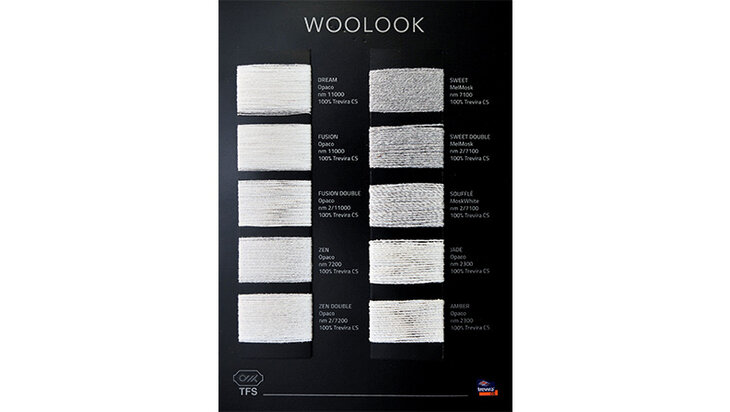

The following customers and partners will join Trevira at the joint booth to present their wide range of attractive, modern Trevira CS yarns and fabrics:

Ambience Home Textiles, Chamatex, Dina Vanelli, Engelbert E. Stieger, FIDIVI Tessitura Vergnano, Gebrüder Colsman, Gebrüder Wylach, Georg + Otto Friedrich, Hoftex, llcat by Leitsu, JAB Josef Anstoetz, Jenny Fabrics, Lodetex, Lonfil, Mattes & Ammann, Mewes, Mottura, Panaz, Pozzi Arturo, Pugi, Spinnerei Lampertsmühle, Spandauer Velours, SR Webatex / Getzner Textil, Tessitura Mario Ghioldi, Tintoria Sala / F.lli Baroni, Torcitura Fibre Sintetiche, VLNAP / Wagenfelder Spinning Group, and Wintex.

“Once again, we rely on our trade fair concept of a joint booth together with Trevira CS customers and partners and once again, we have increased the number of our co-exhibitors. This shows that our concept is successful. This also means that we are able to provide visitors to our booth with an even more extensive overview of Trevira CS products and applications,” says Trevira CEO Klaus Holz.

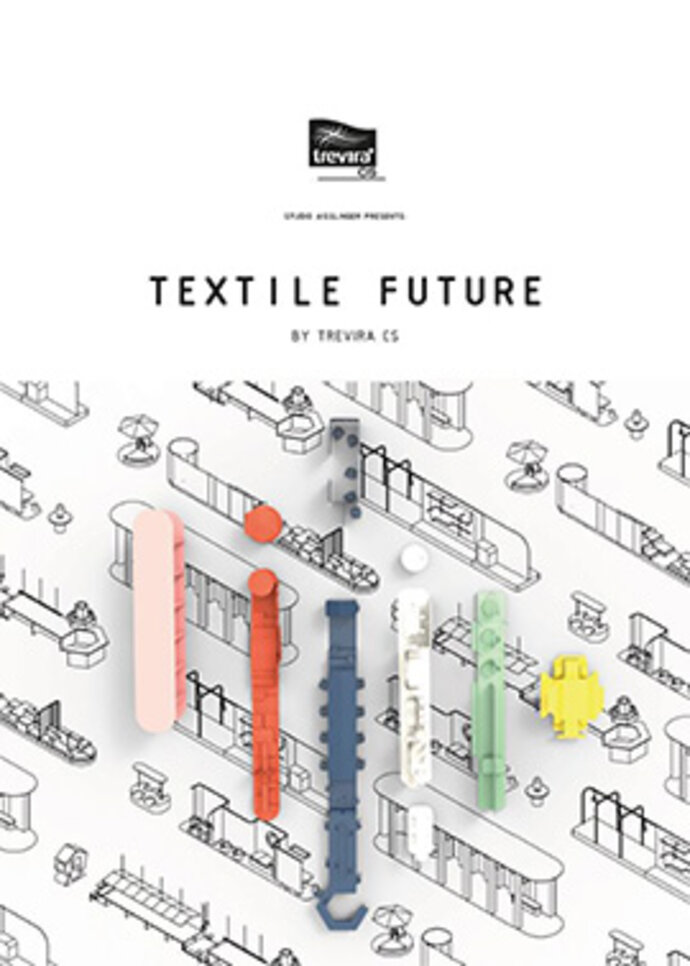

Trevira’s joint booth, which will be situated in Hall 4.2, immediately next to the Messe Frankfurt exhibition “Interior. Architecture. Hospitality. EXPO”, will also feature a special showcase, “Textile Future by Trevira CS” especially for the contract market. To curate this special display, Trevira is proud to have secured a collaborative partnership with renowned Berlin design company studio aisslinger. The studio is known for its outstanding work in experimental and product design, innovative materials and architectural concepts. As a designer, studio founder Werner Aisslinger is particularly interested in how the latest technologies and unusual materials can be used in product design. In addition to designing furniture, his most recent projects mainly include interior design concepts for hotels and workspaces.

The special exhibition, “Textile Future by Trevira CS”, will give visitors, especially architects, interior designers, and decorators, an opportunity to find out more about future-oriented, innovative applications of Trevira CS fabrics on the contract market.

“With our Heimtextil 2020 trade fair booth, we again look forward to offering a networking platform that will be of special interest to decision-makers on the contract market. Our aim is to provide not only an extensive overview of Trevira CS products and collections but also to inspire visitors to rethink textile applications for future projects in the areas of public spaces, workspace, hospitality, health and care, as well as mobility. Our special exhibition will enable visitors to do just that, away from actual projects,” says Anke Vollenbröker, Head of Marketing at Trevira GmbH.

© Trevira GmbH | Trevira stand Heimtextil 2020