About Indorama Ventures

Indorama Ventures Public Company Limited, listed in Thailand (Bloomberg ticker IVL.TB), is one of the world's leading petrochemicals producers, with a global manufacturing footprint across Europe, Africa, Americas, and Asia Pacific. The company's portfolio comprises Combined PET, Fibers, and Indovinya (formerly Integrated Oxides and Derivatives). Indorama Ventures' products serve major FMCG, agricultural, lifestyle, and automotive sectors, including beverages, hygiene, personal care, tire, and safety segments. Indorama Ventures has about 26,000 employees worldwide and reported revenue of $15.6 billion in 2023. The company is listed in the Dow Jones Emerging Markets and World Sustainability Indices (DJSI).

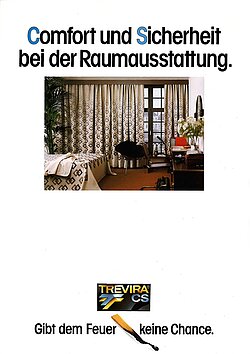

About Trevira CS

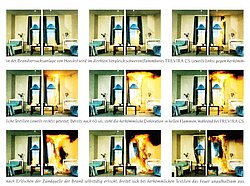

Trevira CS®, a brand of Indorama Ventures, marks fabrics that have been tested for fire safety and have received a Trevira CS trademark approval. They meet the requirements of the relevant international home textile fire safety standards and can be certified according to the IMO regulations for the maritime sector.

Being fully integrated, the production of both the modified flame-retardant staple fibers and filament yarns, all take place in house. Two production sites which manufacture the permanently flame-retardant polyester suitable for Trevira CS are based in Germany. Unlike fabrics with a flame-retardant finish, which can lose their initial protection through use, aging or frequent washing, Trevira CS textiles offer long-term safety. This is due to the chemical structure of the polyester fiber: the flame-retardant properties are firmly anchored in the fiber and cannot be washed off.

For media inquiries, please contact

press.fibers(at)indorama.net

Svenja Fromm, Fibers Communication and Brand Management

Indorama Ventures Fibers Germany GmbH, tel. 0049 015129202459

Follow us on Social Media:

LinkedIn Trevira CS https://www.linkedin.com/company/trevira-cs

Indorama Ventures https://www.linkedin.com/company/indoramaventures

Trevira CS https://www.instagram.com/treviracs/