Trevira CS at the 2023 Heimtextil Trade Fair:

Partnership, innovation, sustainability ... and loads of talent

Trevira CS Joint Booth with 18 Partners at 16 stands

The Trevira CS brand is presenting itself with 18 top customers at Heimtextil, which will be held in Frankfurt from January 10 to 13, 2023. The joint stand is located in Hall 4.0 / Stand C15 and covers an area of over 1,400 m².

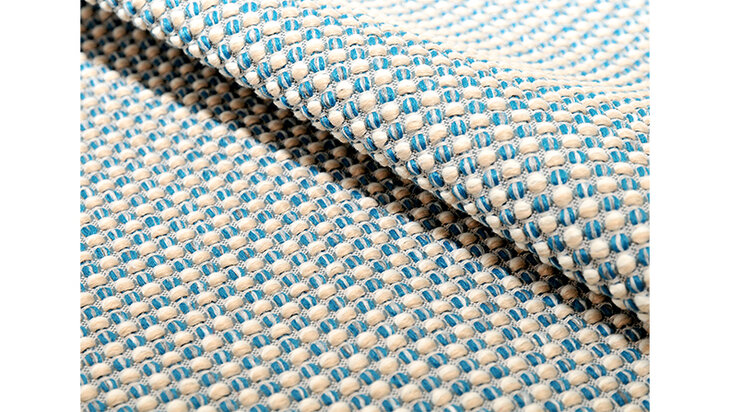

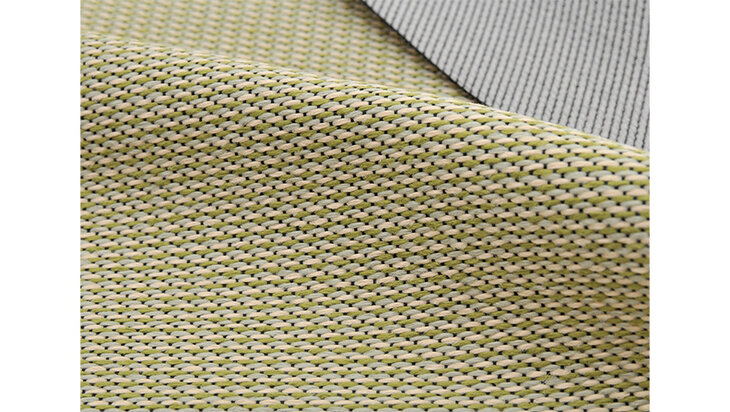

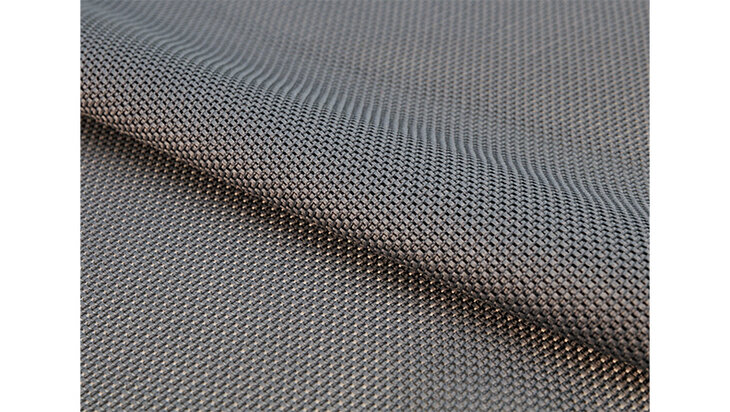

Trevira CS customers and partners will be exhibiting their flame retardant products and new collections for the home textile and contract market at individual stands at the joint booth. Once again, all kinds of textile applications will be showcased by the exhibitors at this year’s Trevira CS booth. Their products include spun and textured yarns, curtains, decorative and upholstery fabrics as well as products for interior sun protection.

The following Trevira CS customers and partners will be exhibiting a wide variety of flame retardant yarns and Trevira CS fabrics at the joint booth: Chamatex SAS, F.lli Baroni s.r.l., FIDIVI Tessitura Vergnano S.p.A., Hoftex Färberei GmbH, Ilcat by Lei Tsu s.r.l., Lodetex S.p.A., Lonfil S.r.l., Mattes & Ammann GmbH & Co. KG, Mottura S.p.A., Pozzi Arturo S.p.A., PUGI R.G. S.R.L., Tessitura Mario Ghioldi & C. s.r.l., Tintoria Sala s.r.l., Torcitura Fibre Sintetiche S.p.A., Torcitura Padana S.p.A., Vlnap a.s., Wagenfelder Spinnereien GmbH and Wintex S.r.l.

© Trevira GmbH | Trevira CS Joint Booth at Heimtextil 2023