Recycling is important for staple fibres too. We are working with our sister company Schoeller GmbH & Co. KG to develop cable types from recycled materials that can be used in the automotive industry, and we expect to obtain GRS certification for these products in the near future. Flame retardant, recycled Trevira staple fibres are also currently at the development stage.

We have already been awarded GRS certification for our recycled combed tops, which are deployed in polyester-wool mixes (55% PET/ 45% wool) for corporate wear and uniforms.

Another important element of our sustainability policy is the manufacture of staple fibres without using antimony. We began to produce our staple fibres from normal polyester on an antimony-free basis as long ago as January 2018, and antimony-free flame retardant staple fibres will be offered by Trevira as a standard from the second half of 2019. This will help us to meet the market demand for specific applications.

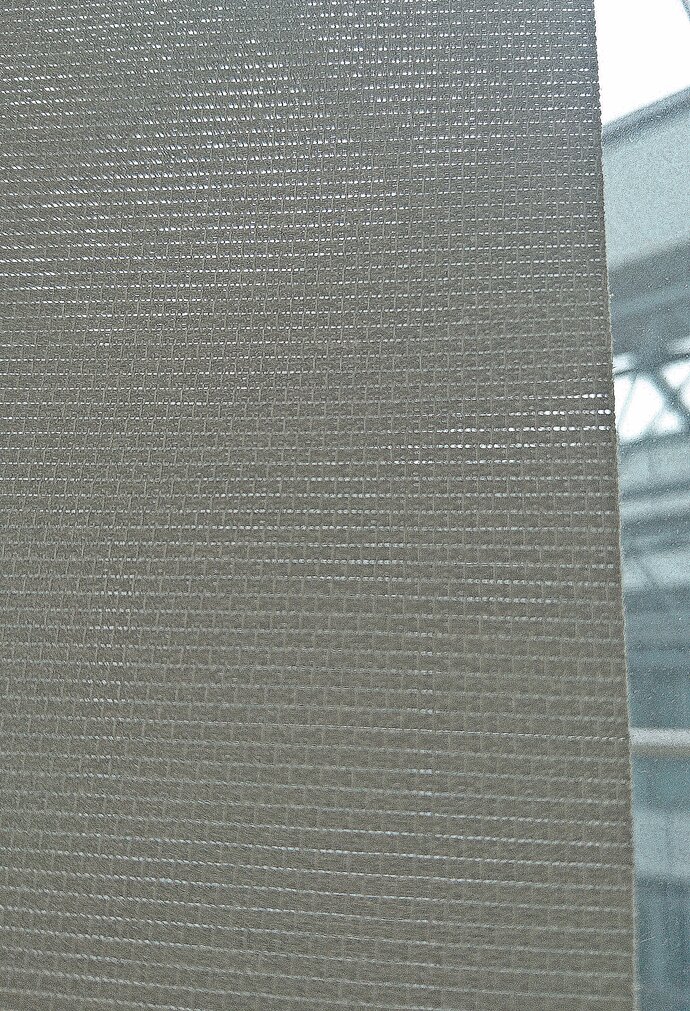

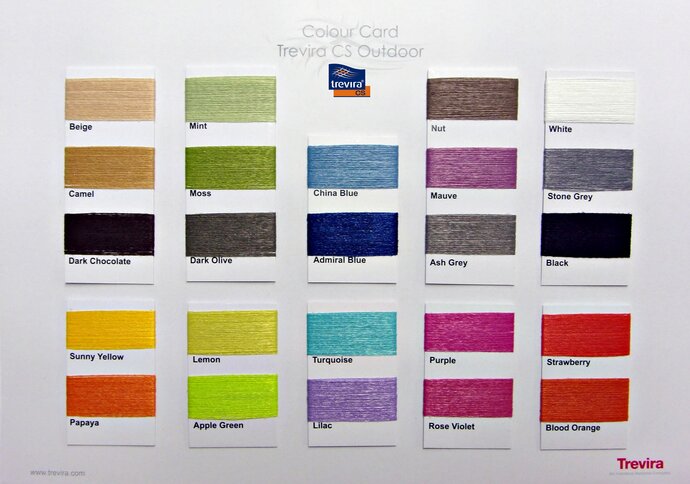

Another innovation in the area of filament yarns for flame retardant polyester home textiles can be seen in the use of Trevira CS fabrics for the outdoor sector. The hotel, restaurant and shipping sectors rely on fabrics that are equally suitable for outdoor and indoor use. Indoors, fabrics must comply with stringent fire safety legislations. Outdoors, they must meet safety requirements while also offering high fastness to light.